■Materials

Stainless Steel (301, 304, 316, etc)

Nickel & Nickel Alloys

Copper Alloys(Beryllium Copper, Nickel Silver, etc)

Others.(Titanium, etc)

■Available Range of Manufacturing |

Item |

Maximum |

Minimum |

Thickness(㎛) |

100 |

8 |

Width(mm) |

300 |

5 |

■Dimension Tolerance |

Item |

Maximum |

Minimum |

Thickness(㎛) |

±2 |

±1 |

Width(mm) |

±0.1 |

±0.05 |

■Available Manufacturing Temper |

Thickness |

Temper |

20㎛ Up |

Annealed, Hard |

20㎛ Down |

Hard |

■Characteristics - Stable and uniform surface condition(Glossy, Surface Brightness, etc.). |

| ■Characteristics

- Stable and uniform surface condition(Glossy, Surface Brightness, etc.). - Precise Dimension ( Accomplishing a micron tolerance in thickness, a minute tolerance in width ).- Wide-ranging products for solving your design issues. |

■Composition |

Com. | Sn | P | Cu+Sn+P |

% | 7.0 ~ 9.0 | 0.03 ~ 0.35 | 99.5up |

■Mechanical Properties |

Temper |

Tensile Strength(MPa) |

Elongation(%) |

Hardness(Hv) |

H |

588 ~ 706 |

20 up |

185 ~ 235 |

EH |

686 ~ 785 |

11 up |

210 ~ 260 |

SH |

686 ~ 785 |

9 up |

230 ~ 270 |

■Available Range of Manufacturing |

Thickness |

0.01mm ~ 0.3 mmt |

Width |

0.3 mm ~ 80mmw |

Coating Materials |

Ag plating : 0.1㎛ ∼ 5㎛ Ni plating : 0.1㎛ ∼ 5㎛ Au plating : 0.0001㎛ ∼ 2㎛ |

■Thickness Tolerance |

Thickness(mm) |

Tolerance(mm) |

0.01 ∼ 0.03 0.04 ∼ 0.08 0.09 ∼ 0.15 0.16 ∼ 0.24 0.25 ∼ 0.30 |

± 0.002 ± 0.003 ± 0.004 ± 0.006 ± 0.007 |

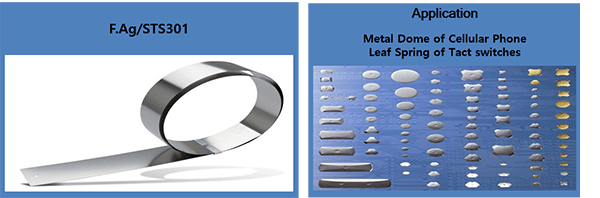

Plated Strips for STS

|

■Characteristics

- Stable and uniform surface condition(Glossy, Surface Brightness, etc.). - Precise Dimension ( Accomplishing a micron tolerance in thickness, a minute tolerance in width).- Wide-ranging products for solving your design issues. |

■Composition |

Com. |

Sn |

P |

Cu+Sn+P |

% |

7.0 ~ 9.0 |

0.03 ~ 0.35 |

99.5up |

■Mechanical Properties |

Temper |

Tensile Strength(MPa) |

Elongation(%) |

Hardness(Hv) |

H |

1,350 ~ 1,600 |

20 up |

430 ~ 500 |

EH |

1,700 ~ 1,950 |

1.0 up |

500 ~ 560 |

SH |

1950以上 |

1.0 up |

540 ~ 600 |

■Available Range of Manufacturing |

Thickness |

0.01mm ~ 0.3 mmt |

Width |

3.0 mm ~ 80mmw |

Coating Materials |

Ag plating : 0.1㎛ ∼ 5㎛ Ni plating : 0.1㎛ ∼ 5㎛ Au plating : 0.0001㎛ ∼ 2㎛ |

■Thickness Tolerance |

Thickness(mm) |

Tolerance(mm) |

0.01 ∼ 0.03 0.04 ∼ 0.08 0.09 ∼ 0.15 0.16 ∼ 0.24 0.25 ∼ 0.30 |

± 0.002 ± 0.003 ± 0.004 ± 0.006 ± 0.007 |

Copper Strips (with Nickel) for Lead Tap Coated by cladding or plating

|

■Characteristics

- Stable and uniform surface condition(Glossy, Surface Brightness, etc.). |

■Chemical Composition(%) |

C1100 |

Item |

Nominal |

Minimum |

Maximum |

Copper |

- |

99.9 |

- |

Oxygen |

0.04 |

- |

- |

C1020 |

Item | Nominal | Minimum | Maximum |

Copper | - | 99.95 | - |

Residual Deoxidants | - | None | - |

■Typical Surface Conditions |

Item |

Contents |

Roughness( ㎛ ) |

0.1 ~ 0.2 |

Brightness( GU ) |

200 ~ 300 |

■Dimension Tolerance |

Item |

Contents |

Thickness(mm) |

±0.005 Down |

Width(mm) |

±0.5 Down |

■Coating(Following Customer's Request)-Clad or plating |

Material |

Thickness(㎛) |

Nickel |

0.5㎛ to 50%(Total thickness) |

■Physical Properties |

Item |

Electrical Conductivity(%IACS) |

Thermal Conductivity(W/(m*K)) |

Specific Gravity |

Poisson's Ratio |

C1100 |

100 |

391 |

8.91 |

0.33 |

C1020 |

101 |

391 |

8.94 |

0.33 |

■Mechanical Properties |

Temper |

OH |

1/2H |

H |

Tensile Strength(MPa) |

Min. 195 |

235 ~ 315 |

Min. 275 |

Elongation(%) |

Min. 35 |

Min. 15 |

- |

Hardness(Hv) |

Min. 50 |

75 ~ 120 |

Min 80 |